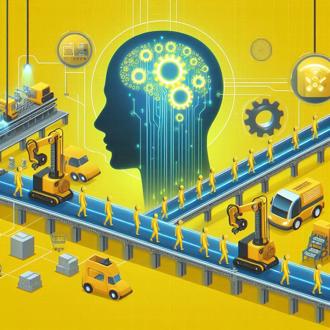

Supercharge Your Production with AI-Powered Production Line Tracking

Monday, 29 July,2024

Introduction

In today's fiercely competitive manufacturing landscape, optimizing production lines is crucial for success. Enter Artificial Intelligence (AI)-supported Production Line Tracking Systems - a revolutionary concept that empowers businesses to achieve peak performance. This innovative technology has the potential to significantly improve efficiency, minimize errors, and ultimately, maximize profits. This blog post delves into the world of AI-powered Production Line Tracking Systems, exploring their functionalities, benefits, and real-world applications across various industries.

Artificial Intelligence Supported Production Line Tracking System

What is an AI-powered Production Line Tracking System?

An AI-powered Production Line Tracking System can be defined as a software solution that utilizes artificial intelligence to monitor and analyze real-time data from your production line. It works by collecting data from sensors embedded throughout the line, such as machine performance, product quality, and production speed. This data is then fed into an AI engine that analyzes it for patterns and anomalies.

Think of it like having a highly observant and intelligent assistant constantly monitoring your production line. It can identify potential bottlenecks, predict equipment failures, and even suggest process optimizations in real-time.

Use Cases and Industry Applications

The beauty of AI-powered Production Line Tracking Systems lies in their versatility. Here are some prominent examples of how they benefit various industries:

- Manufacturing: These systems can track raw materials, product movement, and machine performance. This allows for real-time adjustments to production schedules, preventing delays and ensuring on-time deliveries.

- Automotive: AI can monitor assembly lines, identify defective parts early on, and prevent faulty vehicles from rolling off the production line. This translates to significant cost savings and improved quality control.

- Food & Beverage: Production lines in this sector often involve complex processes with strict quality control measures. AI-powered tracking helps ensure food safety by monitoring temperature, ingredients, and expiration dates, preventing product recalls and maintaining consumer trust.

Benefits

AI-powered Production Line Tracking Systems offer a compelling array of advantages that can revolutionize how businesses operate. Here's a closer look:

- Cost Savings: Studies show that these systems can generate cost savings of up to 20% by optimizing resource allocation, reducing downtime, and minimizing waste. For instance, a company using AI to track raw materials usage reported a reduction in expenses of $100,000 annually.

- Efficiency Improvements: By identifying bottlenecks and streamlining processes, AI can dramatically improve production efficiency. A reputable industry report revealed that AI-powered tracking systems can increase production speed by an average of 15%.

- Quality Enhancements: Through real-time monitoring of production parameters and early detection of defects, AI ensures better quality control. For example, the automotive industry has seen a significant reduction in product recalls since implementing AI-powered tracking systems.

Conclusion

In conclusion, AI-powered Production Line Tracking Systems are no longer a futuristic concept but a powerful tool for manufacturers seeking to gain a competitive edge. By leveraging the power of AI, businesses can optimize their production lines, minimize errors, and achieve their full potential. If you're looking to revolutionize your production process and unlock a new era of efficiency and profitability, consider investing in an AI-powered Production Line Tracking System today.